In the context of digital transformation of the logistics industry, how to improve sorting efficiency and reduce operating costs has become critical challenges for logistics companies. As a leader in intelligent logistics sorting, Wayzim focuses on innovative sorting technologies, providing highly integrated logistics sorting solutions to help customers achieve efficiency leaps and cost optimization.

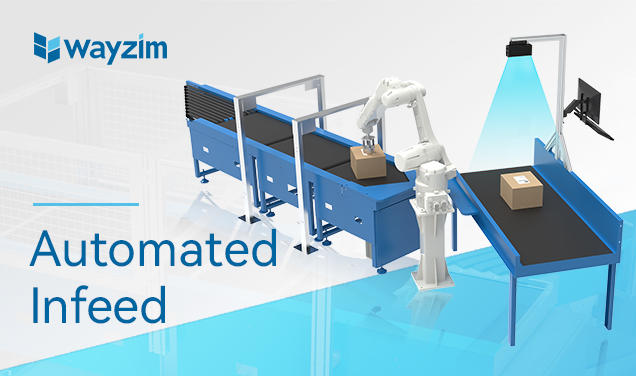

By conducting in-depth research on the project's specific requirements, Wayzim has developed an intelligent sorting solution centered on the "Automated Infeed System and efficient Small Parcel Cross Belt Sorting System." This solution effectively addresses challenges such as space constraints and low sorting efficiency of the conventional infeed methods, significantly enhancing both space utilization and labor efficiency.

By using the Matrix Pivot Wheel Sorting System, optimizing the infeed area layout of the double-layer sorter, and optimizing structures of some double-layer loading lines, the equipment space utilization has reached an impressive 70%.

By using the Automated Infeed System, Cross Belt Sorting System, Matrix Pivot Wheel Sorting System, and other automated sorting and conveying equipment, the project enables automated processing of various types of mail parcels, achieving a daily parcel processing volume of up to 4.752 million mail sacks.

The equipment uses a non-contact power supply, reducing noise and extending the service life. Wear parts such as carbon brushes do not need to be replaced, reducing the replacement and maintenance of wear parts and insulated conductor rail systems. The automated infeed mode enhances the infeed accuracy and efficiency and reduces the need for approximately 32 parcel infeed operators.

To improve space utilization, this project uses a steel platform structure to create two main functional areas: the rough sorting area using matrix pivot wheel sorters at the first floor (F1) and the small parcel fine sorting area at the second floor (F2).

● Large parcel sorting area using matrix pivot wheel sorters (F1)

This area is equipped with 11 rough sorting lines and 9 fine sorting lines. The main conveyor line can maintain a stable running speed of 2.0 m/s, and the peak processing capacity of the area can reach 54,000 mail sacks per hour.

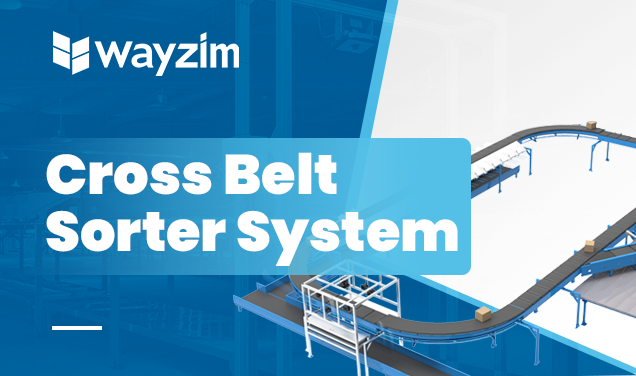

● Small parcel sorting area and consolidation area (F2)

This area is equipped with two double-layer cross belt sorting systems, and each system has 16 automated infeed stations. At each side, two groups of four infeed stations are connected in parallel for fully automated infeed. Each system can process 60,000 mail sacks per hour. In addition, this area is equipped with a single-layer cross belt sorting system, with a parcel processing capacity of 24,000 mail sacks per hour. The total peak processing capacity of this area is 144,000 mail sacks per hour, reducing the need for approximately 32 parcel infeed operators.

● Unloading area

This area uses "two to one" and "three to one" unloading modes to increase the processing flow of the conveyor line and ensure the timely processing of parcels in the special delivery area. The area is equipped with telescoping belt conveyors to achieve efficient loading and unloading, reducing the distance for manual material handling.

The Automated Infeed System independently developed by Wayzim is the core highlight of the solution, enabling the automated infeed and efficient and stable sorting of various types of parcels. In addition, our technicians developed the site plan by using a professional logistics layout concept. Double-layer cross belt sorting systems are used to match the high infeed efficiency, meet the peak processing capacity of the main conveyor line, and complete the seamless connection of the automated parcel sorting processes.

Improving quality and efficiency while reducing costs is the common direction and goal of current logistics companies and many manufacturing enterprises. Wayzim, as a partner for empowering manufacturing enterprises, keenly observes customer needs and continuously optimizes and upgrades intelligent logistics sorting technologies, to enhance comprehensive capabilities.

With each successfully implemented project, Wayzim upholds the commitment to intelligent and eco-friendly logistics development. In the future, we look forward to exploring more new logistics sorting models and approaches with you!